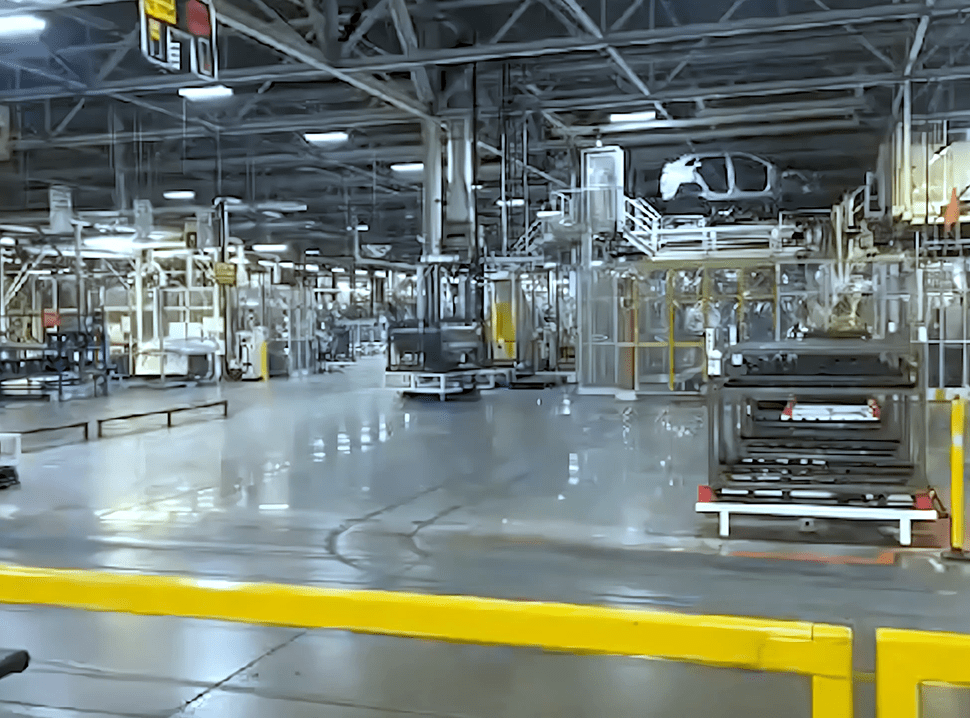

Keep production running seamlessly—no delays in

product retrieval or delivery.

Optimized for tight spaces, seamlessly integrating with

staff, forklifts, and AGV/AMR

systems.

Reduce storage needs and streamline line delivery for faster production cycles.

Works effortlessly with IT/OT setups and multivendor AGV/AMR environments.

Target detection, obstacle

avoidance and alternative

path finding for effective

functioning in dynamic environments.

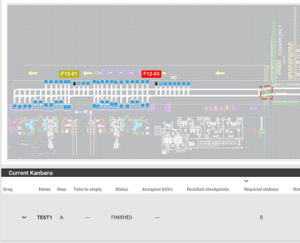

Kanban logic for better

planning, visualization of

workflows and optimizing the

process flow within a warehouse.

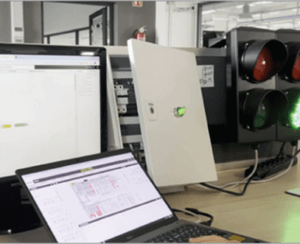

Coordination with automated elements within the factory (traffic orchestration, top modules logic, loading/unloading).

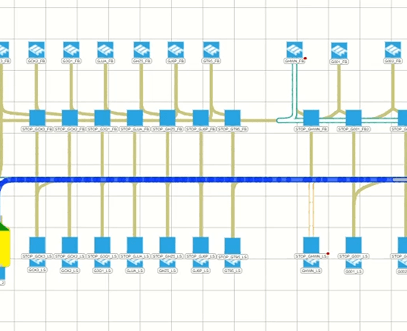

Easy configuration of complex

transfer scenarios that involve more than one AMR enhancing the efficiency of transfer operations.